Industry

Innovation in Automation and Intelligence Among Chinese Sticker Labeling Machine Manufacturers

In the rapidly evolving world of manufacturing, automat [ ]

Industry

How to Simplify Your Moving Process with a Label Maker

Moving to a new home is an exciting milestone, but the [ ]

Industry

What Are Applications And Usage Of ASTM A53 Grade B Piping?

ASTM SA53 pipe, also referred to as ASTM Grade B pipe, [ ]

Industry

Why Glass Ampoules are Important in Pharmaceutical Packaging?

When it comes to the pharmaceutical industry, packaging [ ]

Industry

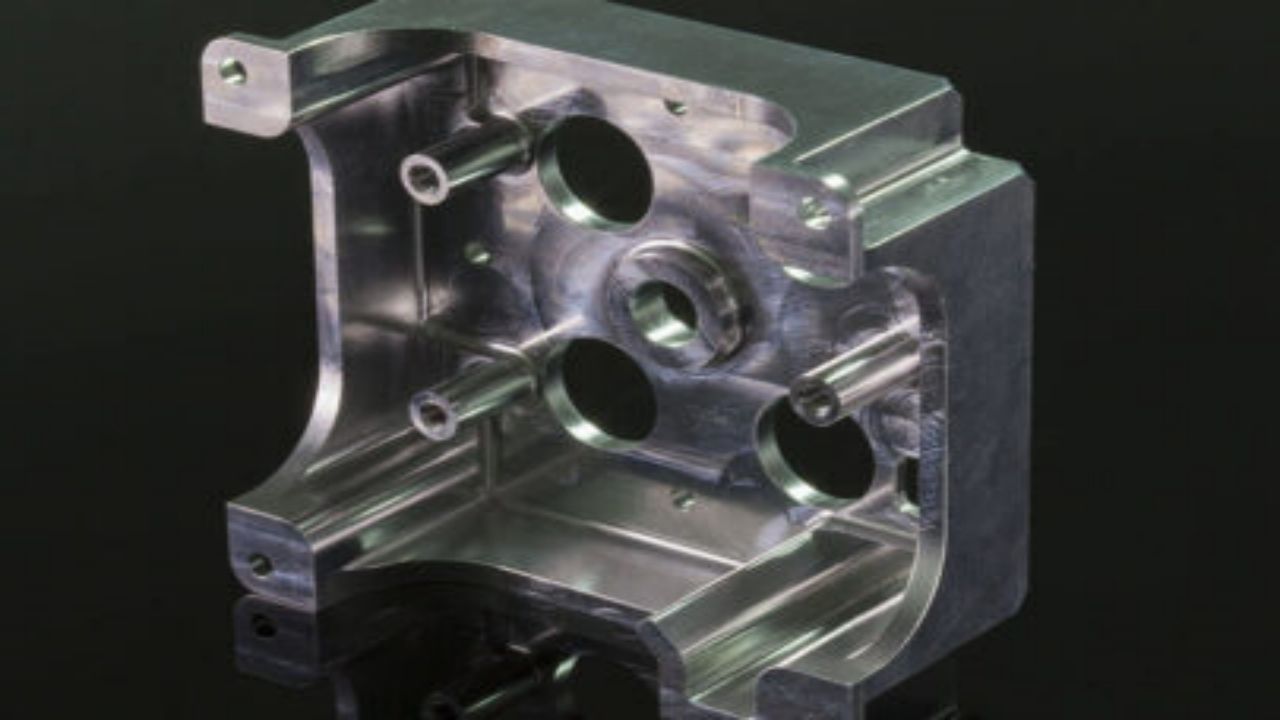

CNC Machining in the Automotive Industry: Unraveling its Impact and Potential

Imagine a world where cars are manufactured with utmost [ ]

Industry

How to Choose the Right ASTM A135 Fire Pipe for Your Needs

Choosing the right fire pipe for your needs is a critic [ ]

Industry

Decoding the Advanced Manufacturing Process and Quality Assurance of Sandvik Stump Grinder Teeth

Sandvik, a world-renowned name in the engineering indus [ ]

Industry

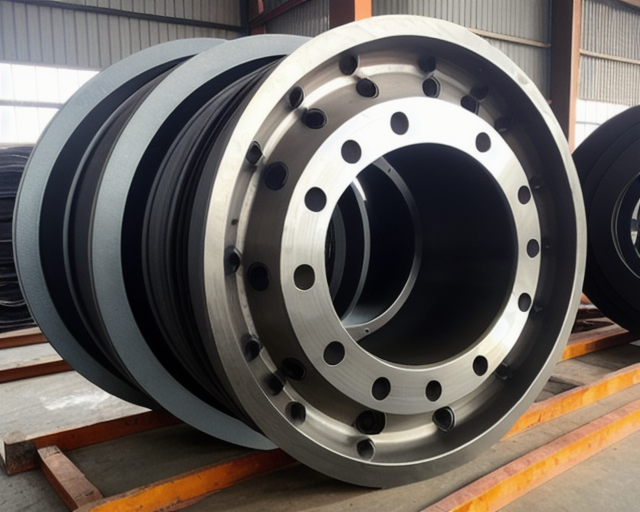

Custom Forging: The Key Process for Achieving Innovative Designs

Innovation is the driving force behind progress in vari [ ]

Industry

The Ultimate Guide to Shrink Wrap Machines: Features, Benefits, and Choosing the Right One

Shrink wrap machines have become an indispensable tool [ ]

Industry

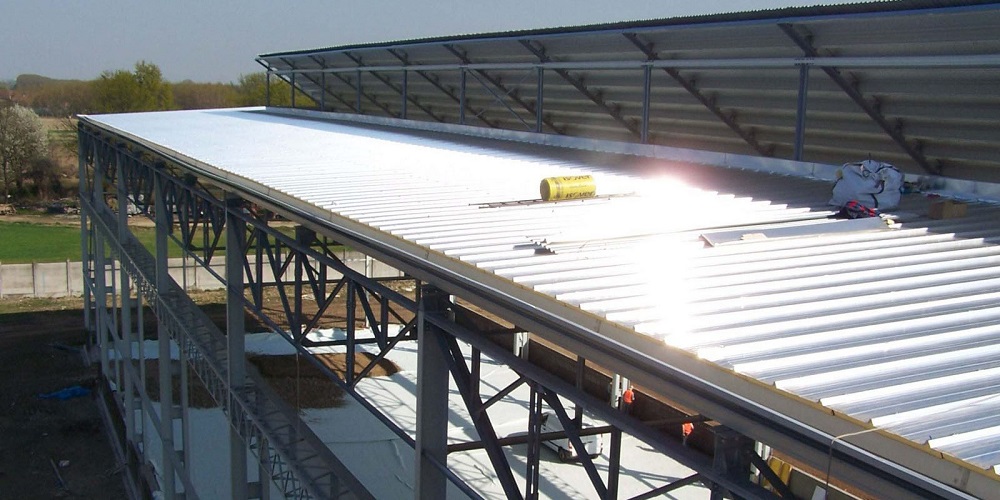

The Benefits of Insulated Sandwich Roof Panels

Insulated roof panels have been around for decades, and [ ]

Industry

Breaking Boundaries with ePTFE Sheet in Automotive Industry

The automotive industry is remarkable in today s [ ]

Industry

Factors to affect the cost of anodizing aluminum parts

Aluminum items are frequently anodized to increase thei [ ]