Unquestionably, online instant quote for manufacturing has made it relatively easy for individuals to place custom-made order products. Besides, the service allows you to choose the material quality you would prefer for your product. Also, the system can provide you with a rapid machining quote immediately after following the necessary procedure provided. In this article, various steps of the process you need to follow for a quotation and manufacturing of the product is discussed.

- Upload the files

The first step for you to get a

quotation on an e-machine

shop, you need to upload a file of the product you want to be made. The

file can be uploaded in various formats such as DXF drawing or STP model.

However, a DXF file can only give cutting jobs price, while STP format can give

both quotations for both bending and cutting cost.

- Choosing

the parameter of the material required

Secondly, you need to select the

thickness of the material to be used. For instance, you can choose a low volume sheet metal forming,

and its thickness will be read from the file. When making the selection, the

material type and the quantity can be selected from the menu. Additionally, special

operations needed, such as surface treatment, can be enclosed in a PDF drawing.

- Choosing

your delivery address

Consequently, you will be required to select

the delivery address for the final product. The shipping cost needs to be

included in the last rapid

quote, hence the delivery address request. After choosing the address,

the system will automatically determine the shipping fee required.

- Accepting

the quote

In the next step, you will be required

to proceed to the payment section. The machining quote calculator will indicate the

amount you are required to pay on the screen. Also, you will be allowed to use

various payment options to choose the one that is more convenient for you.

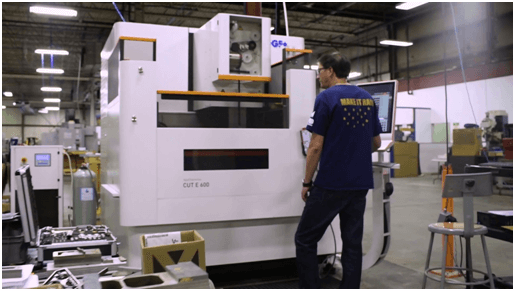

- Production

After the payment as per the machine shop quote template

is made, the manufacturing work begins. The quality of the product in

accordance with the client’s choice should be observed at this stage to ensure

that the final product is produced as per the customer’s choice. Quality

production helps the manufacturer to maintain competence in the market.

- Delivery

After the manufacturing process is over

the final product, custom

CNC parts, for instance, is then packaged and sent to the client. During

this step, the product is always handled with a lot of care to avoid any

damage. Also, the product should be delivered within the expected period.

In

conclusion,

Generally, technology

advancement in manufacturing services has played a vital role in improving

production. For instance, you can get an instant rapid machining quote after following a few simple

steps. Uploading the file of the designed product, selecting the parameter

material, selecting the delivery address, and accepting the quotation given is

all you are required to do for your customized production. Consequently, the

manufacturing firm will proceed to manufacture the item as needed, and then

delivering it to you according to delivery address.