When you are creating a new product for your business, product design, market research, material to use, and the production machine are vital factors to consider. However, if you are planning to produce a unique product for the market, chances are there isn’t any specific machine that can adequately create that product. Fortunately, the CNC prototyping allows you to do this with limited effort. To fully understand how it will help you, below are various advantages and applications of prototype machining that you should know of.

- CNC Prototyping Machine Enables Wide Material Use

One of the significant benefits of the CNC service machine is the wide selection of material you can choose from. Unlike other machines that are customized to only use one kind of material, you don’t need to compromise on the type of raw material you use. A significant benefit of CNC engineering is you can use various plastics and metal in the creation of high-quality products.

- CNC Prototyping Machine Provides Excellent Accuracy

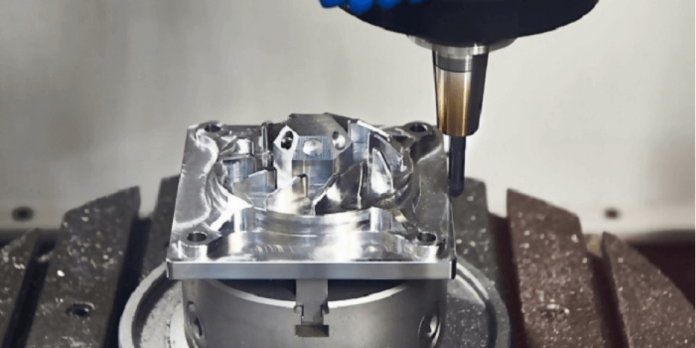

Ideally, the CNC machining cost a lot because of the gauging standardization that it has. Often, when it comes to the creation of new products, the initial process includes a lot of trial and error methods of correcting errors in the design. With CNC machines, the software is created to be highly accurate to cut inaccuracies. The specifications allow for high accuracy that leads to excellent detailing and finishes.

- Fast Turnaround Provided By The CNC Prototyping Machine

It’s essential to keep up with the demand for products to keep abreast of market competition. A primary way of doing this is ensuring there is a constant production of products. In the creation of custom CNC parts, you get the assurance of a fast turnaround of products. With the ability to continuously create new products for 24 hours, you don’t lose time on downtime.

- CNC Prototyping Machine Is Versatile

It’s quite common to invest in several machines when creating a product. Usually, the machines are integral in conducting a wide range of operations that are integral in the production process. However, when it comes to producing CNC on-demand products, this aspect is eliminated. The CNC machine design can conduct several operations allowing you to save money on machine investment.

- CNC Prototyping Machine Is Economical

A vital benefit of the CNC prototyping machine is that it’s customizable. Ideally, this means that you can switch and create a variety of products with ease. Additionally, as it cuts down the production process, it’s considerably cheaper than using rapid prototyping processes. Overall, it is economical as it cuts down on the production time hence making custom CNC work cost substantially less than other production processes.

Conclusion

Investing in your CNC prototyping is beneficial as a business as you don’t rely on a third party in the production of your products. Additionally, you have the freedom to custom and create a multitude of products that would have otherwise been challenging if you didn’t have one. As it’s a key component in the production process, you achieve full control of the engineering and manufacturing process hence having full control of your business.