Imagine a world where cars are manufactured with utmost precision, ensuring top-notch performance, safety, and efficiency. Well, that’s not just a dream but a reality thanks to CNC machining! Let’s delve into the fascinating world of Computer Numerical Control (CNC) machining and its profound influence on the automotive sector. Visit the 3ERP to learn more.

CNC Machining’s Crucial Role in Automotive Components

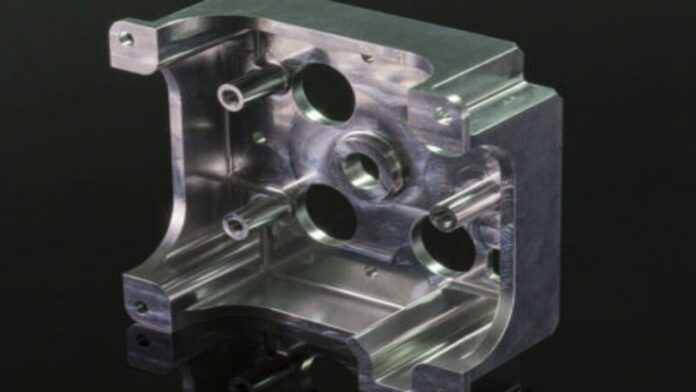

The heart of any vehicle lies in its engine, and CNC machining ensures that the engine components are crafted with utmost perfection. From cylinder heads to pistons, these critical parts benefit from CNC’s ability to achieve tight tolerances and smooth finishes, ultimately boosting engine efficiency and durability. Not just the engine, but transmission parts and even interior components like dashboards also undergo CNC magic, resulting in components that fit like a glove and function flawlessly.

Empowering Automotive Advancements: The Advantages of CNC Machining

1. Precision for Peak Performance

You know how a perfectly-tuned instrument produces beautiful music? Similarly, CNC machining creates harmonious engine parts with unmatched precision. The tight tolerances and consistent quality ensure reduced friction, maximizing vehicle performance and fuel efficiency.

2. Safety and Reliability: No Compromise

When it comes to safety, there’s no room for compromise. CNC machining delivers parts with consistent dimensions, minimizing the risk of failure due to manufacturing defects. This is a game-changer for both manufacturers and drivers, instilling confidence in the vehicle’s reliability.

3. Speed and Agility: Meeting Consumer Demands

In the fast-paced automotive world, staying ahead of the game is crucial. CNC machining allows manufacturers to swiftly prototype and iterate designs, catering to evolving consumer demands efficiently. It’s like having a magician’s wand for automotive production!

Beyond Conventional Designs: CNC Machining Unleashes Creativity

The automotive landscape is not just about engines and transmissions; it’s about design and aesthetics too! CNC machining enables automotive designers to spread their creative wings and craft intricate, personalized designs. No more cookie-cutter cars; with CNC technology, each vehicle can have its unique touch, reflecting the owner’s individuality.

Embracing the Challenges: Future Trends for CNC Machining

1. Uniting CNC with AI for Smart Manufacturing

In the quest for the ultimate efficiency, CNC machining is shaking hands with Artificial Intelligence (AI). AI algorithms optimize machining parameters, leading to even greater precision and productivity. Moreover, imagine fully automated CNC systems working round-the-clock, shaping the future of smart manufacturing.

2. Materials Revolution: Paving the Way for Sustainability

Sustainability is the buzzword, and automotive manufacturers are keen to reduce their carbon footprint. CNC machining is at the forefront of material advancements, exploring lightweight composites and eco-friendly alloys that will revolutionize the automotive landscape. Greener cars, happier planet!

In Conclusion: CNC Machining, Driving the Future of Automotive Excellence

CNC machining has become more than just a manufacturing process; it’s the driving force behind the automotive industry’s quest for excellence. From engines to designs, CNC’s impact is undeniable. It fuels innovation, enhances safety, and brings unparalleled efficiency to car manufacturing.

As we embrace a future of AI-powered smart manufacturing and sustainable materials, CNC machining will continue to be the driving wheel that propels the automotive industry forward. So, the next time you hit the road, remember that behind the wheels of your car lies the brilliance of CNC machining, transforming raw materials into a masterpiece that keeps the world moving ahead!