An induction heating machine is used in various applications, from cooking to metal fabrication. They use electromagnetic induction to heat objects and materials by transferring energy directly. This allows for precise control over the temperature of the heated material and eliminates the need for direct contact with an open flame or another heat source.

How It Works

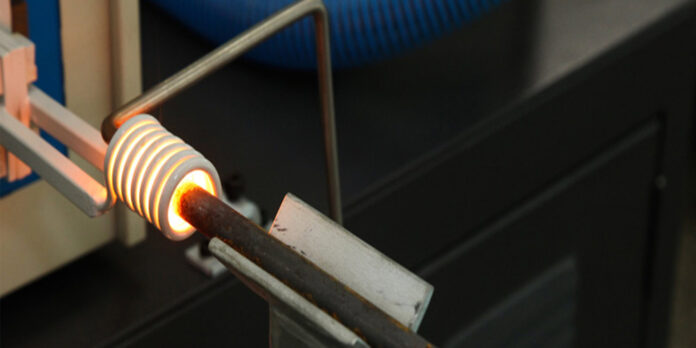

Induction heating machines are devices that use electromagnetic induction to heat materials. They use a coil of wire wrapped around the object to be heated. The coil is energized with high-frequency AC power, creating an alternating magnetic field. This causes the metal’s electrons to oscillate back and forth at high speeds, generating heat in the process.

The heat generated by induction heating is not hot enough to cause any damage to the metal. The heat produced can be controlled by varying the frequency of the AC power supplied to the coil.

Induction heating is used to heat various materials, including steel and other metals, glass, and ceramics. It is also used to heat water in steam tables or sterilization processes.

The Benefits

Induction heating machines are a great choice if you’re looking for a new heating method. Not only do they heat faster than other methods, but they also produce less waste and can be used in many different situations. The benefits of induction heating include the following:

- Efficiency — Induction heaters reach temperatures far faster than other heating methods, which saves you time and energy in the long run.

- Safety — Since there are no open flames or hot surfaces involved with induction heating, it’s an extremely safe way to heat objects without worrying about accidents or burns.

- Versatility — You can use these machines effectively on any material, metal or plastic. There are even special applications for glassware! In addition, these machines have many uses beyond just cooking items like meat or vegetables; they can even be used for cleaning purposes like sanitizing dishes before using them again (or removing grease from pans).

Applications

Induction heating machines heat metal parts, molds, tooling, castings, prototypes, and fixtures. Applications include:

- Die casting – Heat the mold to speed up the cooling process and improve the quality of your component

- Metal finishing – Increase material hardness or reduce surface defects by heating it to certain temperatures

- Welding – Weld parts together without using any filler or fusing materials

Heat treating – Increase the hardness or toughness of metals by heating them to specific temperatures

Forging – Create a mechanical bond between the metal and a forging tool by heating the workpiece to a specific temperature

Injection molding – Inject molten plastic into a mold to create small plastic components.

Conclusion

An induction heating machine is a very useful and powerful tool in any industry. It has many applications in various fields, such as medicine, food processing, and textile. It can also melt metals or other materials, such as glass, to create new products or repair damaged ones. The induction heating machine is a great addition to any industry. The ability to melt and shape different materials, like glass and metal, makes it an essential tool for many applications. It is also possible to use an induction heater in some other industries, such as medicine, food processing, and textile manufacturing.