The world of cables and wiring solutions has never been short of emerging trends. For instance, we can say that the diversity of wires in the market keeps growing. Many brands are currently available in the market, and we can foretell that many are yet to be launched or upgraded. And when it comes to quality and versatility, the universe of wires has a lot to offer. There are numerous and progressive changes that have been made to facilitate various uses and applications. Teflon wire is the most sought after type of cables in the current market due to their features and properties that give them an edge above other kinds of wires.

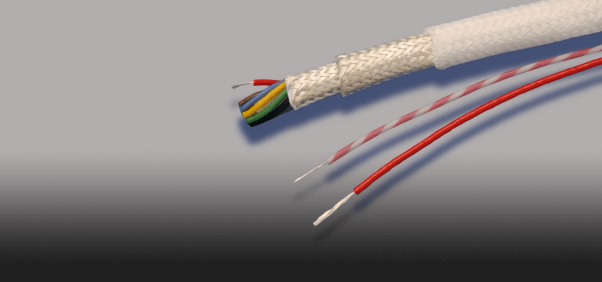

And the variations of the modern Teflon wire have been impressive and continue to impress even more with the changing demands and specifications in today’s markets. There are Teflon plated silver wires, and Teflon coated copper wires that are collectively used for specific reasons. For instance, copper has been used alongside aluminum conventionally in electric cables for transmission of power. But due to adverse weather conditions, these two become unreliable, and therefore Teflon is used as an alternative.

Additionally, Teflon wires have emerged in the universe of wires to significantly improve performance in machines and wiring systems due to its appealing properties. It is worth noting that Teflon is among the few brands of wires that resistant to different ranges of temperature, chemicals, moisture, and power. The features make Teflon simple and effective to use and without significant toil.

The emerging-market values perfect wires. And the perfectness is seen when the wire can withstand the most demanding applications without compromising quality and effectiveness. Teflon has been able to offer all these plus more:

Compelling facets of Teflon wires

- Teflon wires are one kind that possesses high dielectric strength compared to other ordinary cables.

- Teflon wires can operate in high temperatures without being damaged (resistant to extreme temperatures).

- Teflon wires have low dissipation factors and are not affected by vulnerabilities in dampness, liquids, and moisture in the surroundings.

All with the above features, other trendy aspects of Teflon wires are:

- The Teflon insulated wires are suitable for wide frequency ranges.

- The wires can be used as conductors (silver plated).

- Teflon wires provide resistance to ultraviolet radiation, molds, and other chemicals.

- They cannot be deformed over time since they are incredibly flexible.

The emerging use of the Teflon wires

Teflon wires have a range of uses and applications in various industries. Due to their ability to withstand temperature ranges, they are used in electrical resistances and in making materials and home appliances that require any of the features that the wire possesses. However, there has been an emerging trend that has seen Teflon wires applied in the medical field.

Take-Home

There are medical devices that require a smooth coating that can hold still in various conditions. Teflon coated wires are habitually being used as part of therapeutic equipment, insertions, and other different devices.

The universe of wires has never been short of trends, and Teflon is increasingly becoming one of the emerging trends every day. Be it in the application, use, or type, Teflon has everything trendy in it.