Have you ever wondered how metal parts are manufactured considering how hard it is to curve metal items? Well, metal parts are produced in a process called die casting. During the process of die casting, metal parts are made by forcing metal in molten form into die or mold cavity under extremely high pressure. The mold cavities used in this process are made from hardened tool steel that is machined to the net shape or shapes very close to the pure form of the parts of the die-cast. Through die casting, metal parts, textured surfaces, or names can be conjured accurately and repeatedly without requiring further processing.

Types of die casting

There are two main types of die casting.

- Hot Chamber Die Casting

This is a form of die casting where an injection is immersed in a pool of molten metal. A furnace is attached to the machine through a gooseneck, which is also often referred to as the feeding system. The first step in this type of die casting is the retraction of the piston. This is when the molten metal fills up the feeding system causing the plunger to move downward. The molten metal passes through a port in the injection cylinder.

The downward movement of the plunger causes the die casting machine ports to be sealed and the molten to move from the gooseneck towards the nozzle. The nozzle then leads the molten metal into the die.

Once the metal has been colored, it is left to dry up and solidify. The plunger then pulls upward, causing the die to open and the processed metal part to be ejected.

While this process is quick, the downside is that it cannot be used to manufacture alloys that can attack the injection cylinder.

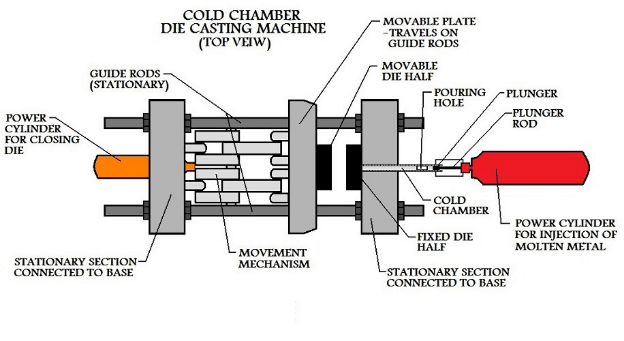

- Cold Chamber die casting

Here a ladle used to transport the molten metal from the holding chamber, which also happens to be a furnace in an unheated shot chamber and in some cases, an injection chamber. From this chamber, the metal is shot into the chamber containing die using a hydraulic piston.

While this type of die casting is relatively slower, it is the only what through which molten aluminum alloys can be processed since they tend to attack and to cause metal cylinders, plungers, and dies to erode. This may result in die casting machine life-shortening. Cold chamber die casting can be used as an alternative to keep this from happening.

The type of die casting that is used by the metal part manufacturers depends on the type of metal that is being worked on and the speed in which the manufacturer needs to complete a project.

Final Word

The main advantage of die casting is that different parts and products can be produced in a range of shapes and sizes without any limitations. The most common products made from die casting include engine parts, cast-iron pots, pans, and other vehicle parts made from hardened metal.